Portable pumps are used routinely for EMS but infrequently in hospital settings. The most common uses for a portable suction unit are the unconscious patient, airway clearance, and trauma patient. For airway clearance in areas that do not have ready access to central suction, they may be your only option, and the reason you will often see portable pumps on the side of your crash carts. Portable pumps present distinct issues when pressed into other services:

Airflow

Portable pumps typically only have 25% of the wall suction flow (20lpm vs. 89lpm). Specific clinical applications such as chest drainage and external female catheters rely on high airflow to properly work.

Noise

Portable Pumps typically do not comply with sound level directives for modern ICUs. Infrequent use during a code fits within these requirements, but routine usage would degrade the patient care environment.

Service Life

Many portable pumps are rated for 30 minutes of continuous usage; look at the fine print in the manual.

Cross Contamination

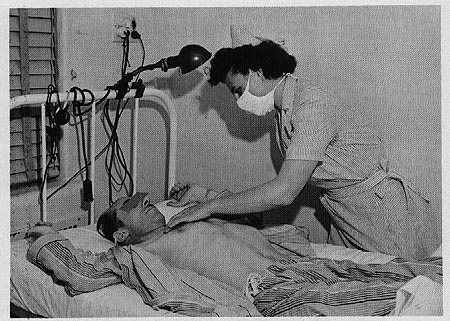

There was a big push in the 1960s for hospitals to embrace central suction systems based on numerous articles showing bacterial cross-contamination from aspiration pumps commonly used. You could not accredit an acute care hospital without central suction. Modern canister systems typically have fluid shutoffs but lack bacterial filters. Even with bacterial filters in place, viruses quickly go through them.

In setting up mobile medical units, whether in tents, repurposing existing buildings, or modular units, the ideal circumstance would be to connect to the central suction system. However, they will most likely not have access to the hospital’s central suction system. If portable pumps are the only option, contamination is a significant concern for an airborne virus. Even if disinfected between uses, a portable pump mechanism works by collecting fluid in a canister, and aerosolized particles are aggressively blown out the back of the unit during use.

Back to Blog